Reducing Downtime with

Predictive Maintenance

PREMAS 4.0 / Schade Lagertechnik GmbH

PREMAS 4.0 is the ideal solution for predictive and effective maintenance of conveyor systems. Service personnel can monitor all important production parameters using the software. This helps avoid failures and unforeseen malfunctions, ensuring smooth operation of the plant. Furthermore, production efficiency is maximized.

Challenge and Use

The developed software is used for bulk storage yards and blending beds in various industries, including cement, iron, steel, and aluminum industries, power plant industry, mining & minerals, alternative fuels, as well as ports and terminals. In the first step, the challenge was to create awareness of the importance, relevance, and significance of the data and then to develop comprehensible visualizations together. The quickly comprehensible infographics developed, for example, regarding the wear of individual machines, contribute to predictive maintenance of the plants, thus leading to a significant improvement in overall operation.

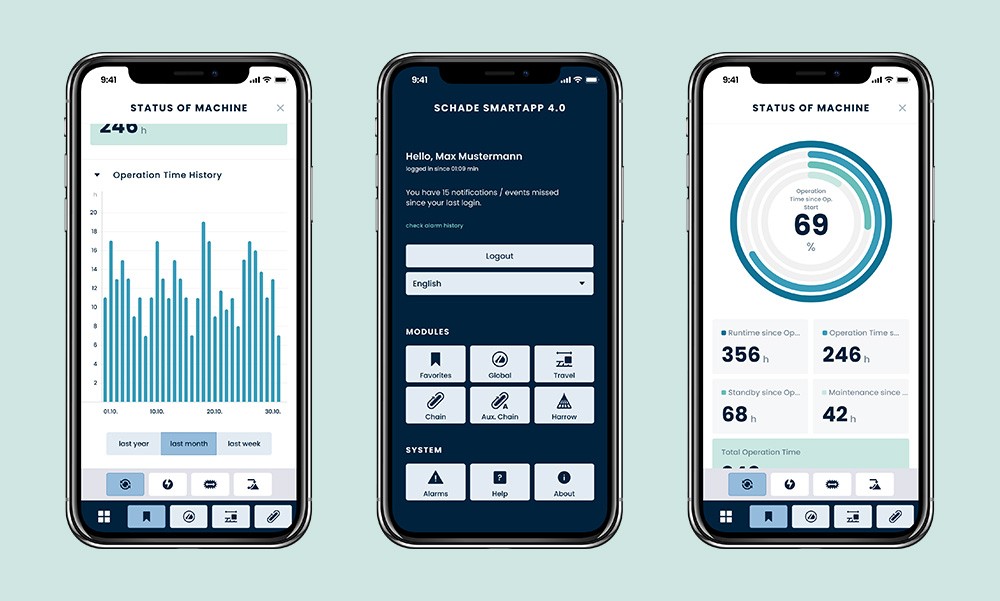

Quick Overview from Anywhere

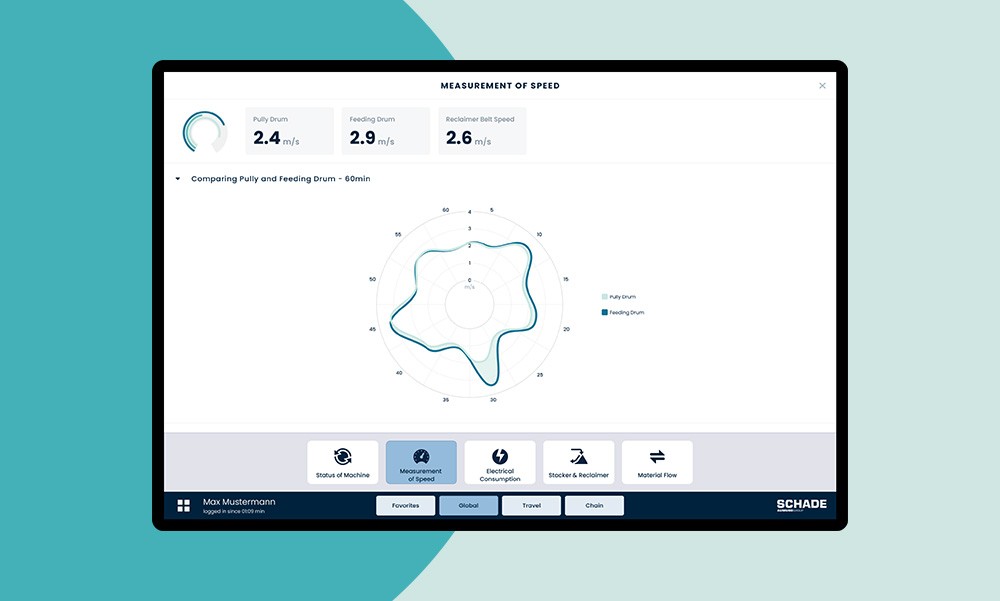

Whether on the road or at the workplace, service technicians can view their plant's maintenance data from anywhere using the relevant key figures thanks to the responsively designed software. The individual dashboards and clear infographics enable technicians to quickly gain an overview of the status of their systems. In detail, a detailed trend display over time and help texts are available to them.

Sophisticated Design

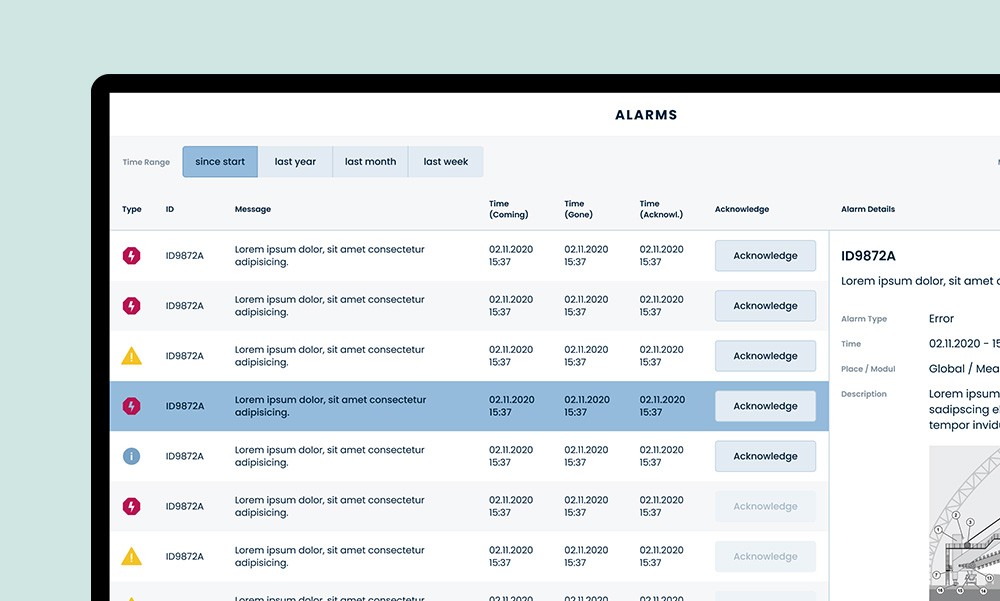

The graphic design is derived from the corporate design of the manufacturer and the associated group of companies. With its restrained colors, the design offers an ideal platform for warnings and error messages. These can attract the attention of service technicians in signal colors, indicating problems quickly and reliably. Downtime can thus be avoided through preventive maintenance.

Created with HELIO

The frontend was implemented using web technology and based on our HMI management system HELIO. The complete frontend is configurable in terms of content using the HELIO Content Editor, and can be adapted to new machine types and purposes.

Vimeo

External Video

We host our videos on Vimeo. When the videos load, a connection to Vimeo servers is established and cookies are set (possibly also from Vimeo).

Privacy