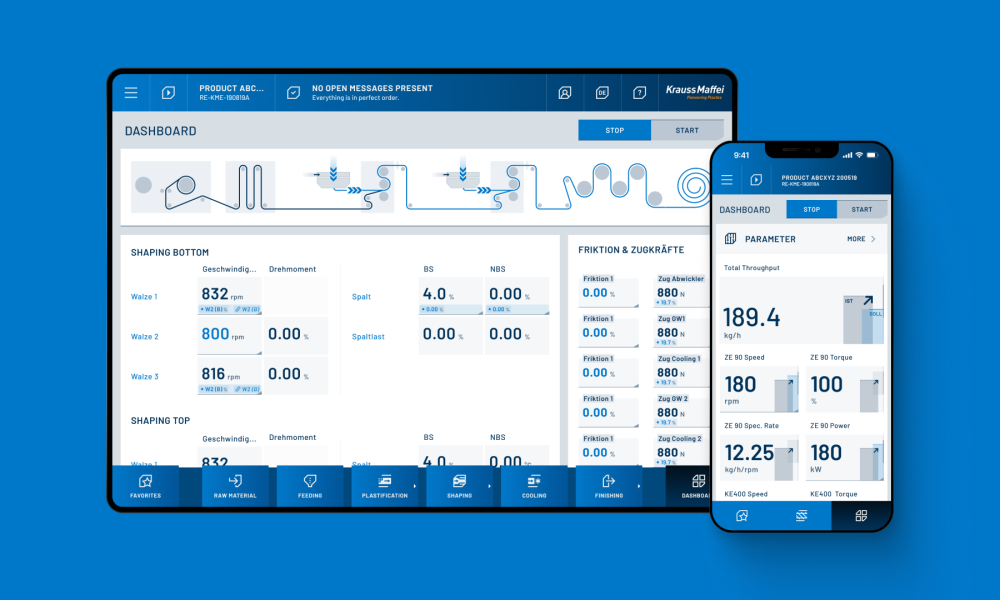

Corporate User Interface

for Plastic Production

pioneerProcessControl / KraussMaffei GmbH

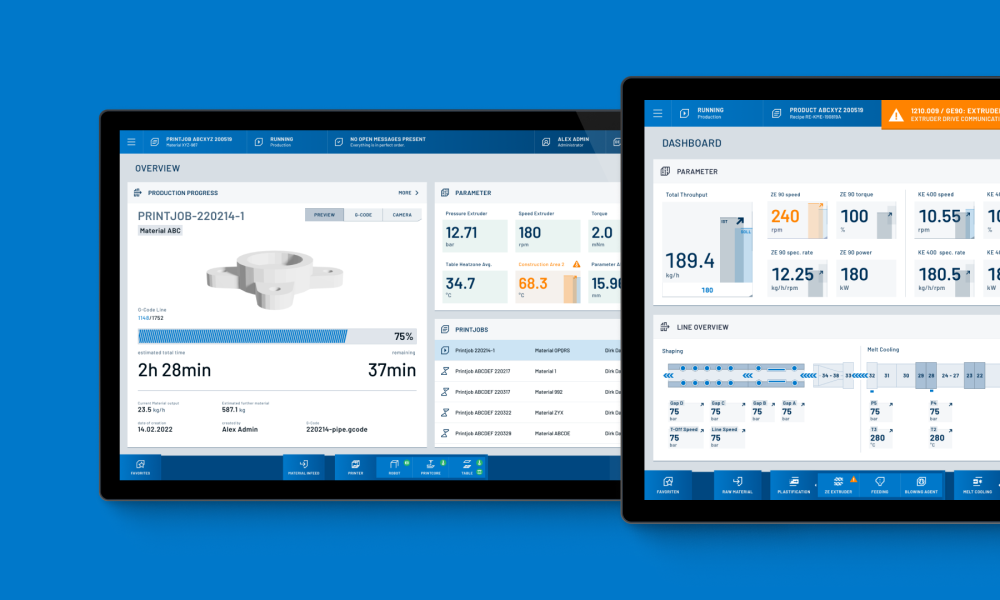

›pioneerProcessControl‹ started as a project solution for operating extrusion plants and has now established itself as a cross-functional corporate UI for KraussMaffei. The new intuitive operating principle was developed with a user-centric approach and captures all forms of previously existing UIs, harmonizing and simplifying them. The innovative, process-oriented navigation and the seamless integration of guided workflows and interactive visualizations create a unique user experience.

Challenge and Application Area

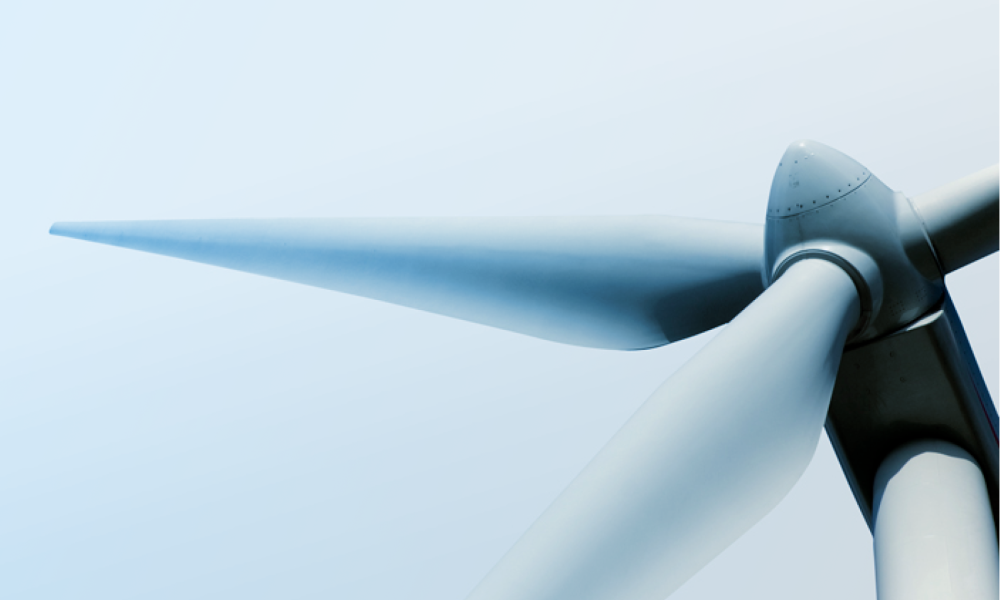

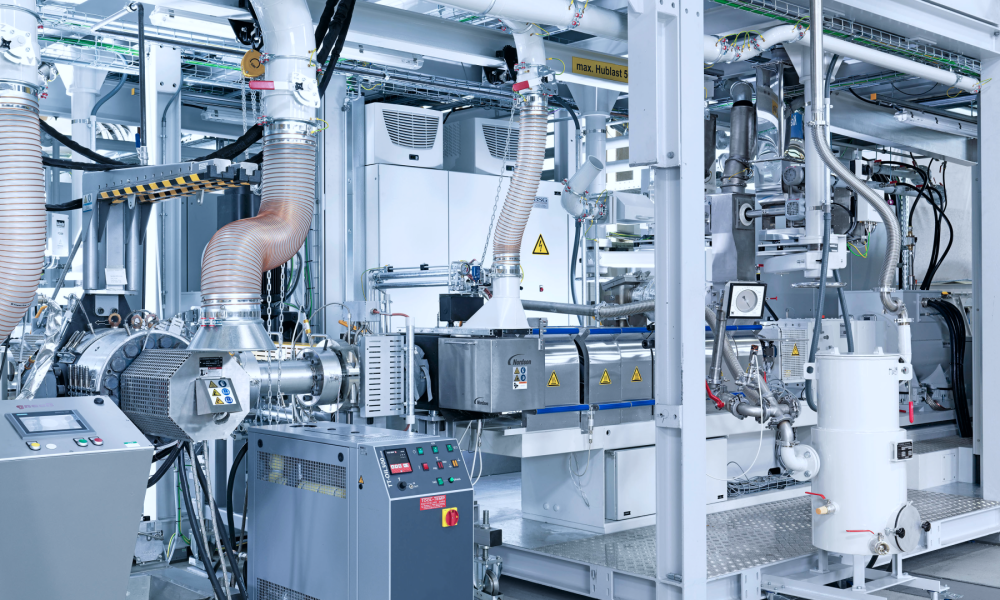

The KraussMaffei Group is a globally operating company whose portfolio includes all technologies of injection molding, extrusion, and reaction molding. For KraussMaffei Extrusion GmbH, the world's leading manufacturer of machines and systems for the extrusion and recycling of plastic and rubber products, a comprehensive and flexible concept and design were developed in an initial project. The goal was to simplify and harmonize the complex and heterogeneous forms of previously existing UIs.

With the goal of adapting the operating principles and design to other business areas, we developed a global corporate UI that reflects the essential aspects of KraussMaffei's corporate design and contributes to a uniform brand presence.

Simple and Understandable

With the integration of detailed step-by-step instructions, we have created the perfect solution to break down complex processes, make them more understandable, and accessible even to less trained operators. The reduced design language, with visually supporting illustrations and interactive representations, also contributes to better understanding. The focus is primarily on the most important and production-relevant parameters and functions. A well-thought-out notification system completes the monitoring of production.

User-Centric and Process-Based

The process-based navigation provides intuitive and fast operation. Through a consistent dive-in principle, expert settings can be easily separated from everyday functions. The result is an optimized representation of user-centric, role-based, and process-based content in combination. This principle was tested and validated in advance through extensive analyses, user surveys, and prototypes.

Vimeo

External Video

We host our videos on Vimeo. When the videos load, a connection to Vimeo servers is established and cookies are set (possibly also from Vimeo).

PrivacyBeyond Extrusion

Already at the beginning of the project, the goal was formulated to develop a flexible standard that could also be transferred to other business areas (automation, injection molding, etc.) in the future. Therefore, we did not develop a simple project solution, but a complex but consistent and globally applicable corporate UI. In addition to the extensive component library, a style guide was created, which, in addition to documenting overarching design patterns, also provides all components and freedoms for individual solutions for various departments.